SARAUER

HOROLOGY

SH1 Movement

The SH1 movement for Ref. 119C has been designed in-house, featuring a classic hand-wound manual construction. It leverages key components from the reliable ETA 6498 gear train and setting mechanism, yet diverges significantly with a bespoke redesign tailored for a more compact case profile. This necessitated a complete overhaul of the foundational movement architecture, involving precision machining of every element from raw materials to ensure seamless integration throughout.

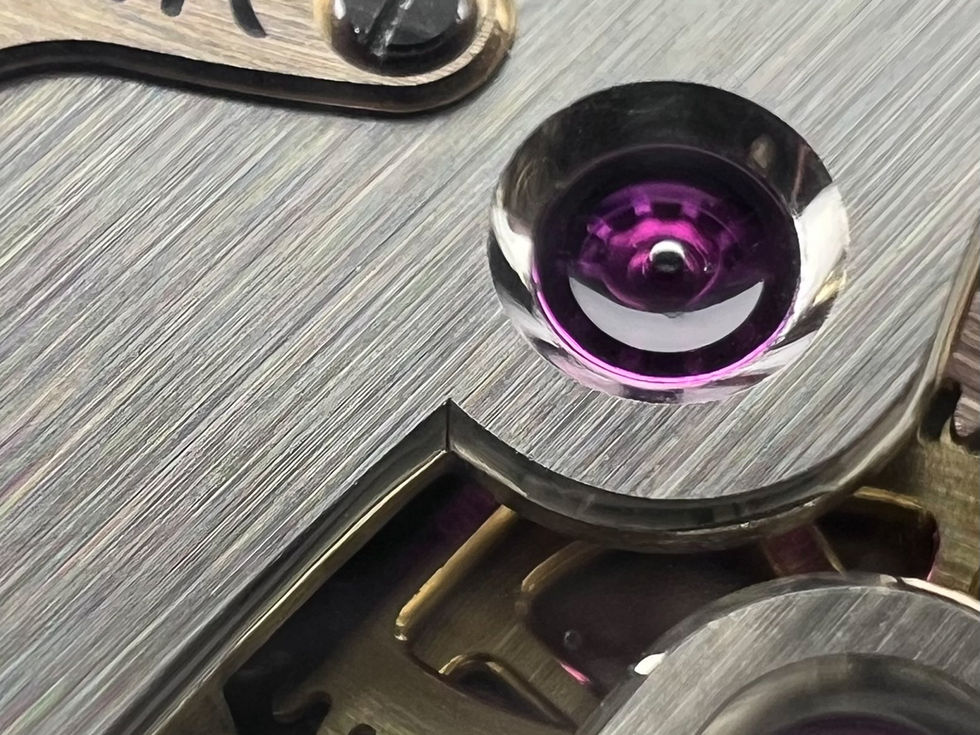

From mainplates, bridges, and springs to balance and regulation mechanisms, each component has been carefully redesigned and machined to achieve a harmonious movement. The design showcases multiple finishes including straight and circular graining, frosting, perlage, inward angles, heat tempering, and black polishing, underscoring a commitment to haute horology.

The mainplate and train bridges are crafted from German silver, a material reserved for superior caliber movements. Noted for its untreated surface that develops an attractive patina over time. Raw German silver facilitates easier refinishing compared to plated brass, and its inherent non-magnetic properties further enhance reliability.

The Sarauer name and number plate is made of solid 14K gold and paint filled. The pallet fork bridge is made of steel.

The unified aesthetic of the steel click and balance regulator spring, with polished bevels and locating pins, exemplifies a blend of functional design and aesthetic appeal.

Attention to detail extends to the beveled and polished ratchet and crown wheel teeth, reminiscent of Lang & Heyne standards, complemented by polished sinks and fine snailing on the faces. The crown features a unique core design secured beneath the barrel bridge.

The gear train wheels adopt a classic 5-spoke design with painstakingly hand-beveled corners, each adorned with 20 inward angles. Once beveled the wheels are circular grained and riveted to the polished pinions. The barrel is circular grained or snailed.

The balance wheel, a pinnacle of precision machining, undergoes meticulous craftsmanship to ensure optimal timekeeping. From drilling and tapping 0.40mm holes for timing weights to hand-forming Breguet overcoils, every step contributes to enhancing the movement's isochronism and accuracy. The regulation system is a hallmark of the SH1 movement, integrating a Breguet overcoil and regulating pins for fine-tuned adjustment, complemented by a flat-polished arm and an eccentric screw for precise calibration.

On the dial and setting side, significant geometric alterations from the original caliber necessitate bespoke machining of components like the canon pinion, setting lever jumper, and hour/minute hand wheels. Although these components remain unseen, each is finished to the same rigorous standards upheld throughout the entirety of the movement.

The movement screws are flat polished with options for tempered colours to enhance aesthetic appeal. The ratchet wheel screw features a distinctive Robertson type head, a nod to its Canadian heritage, specially created for the Ref. 119C model.